Our plants are designed with the highest quality of fabrication standards using the best components and instruments.

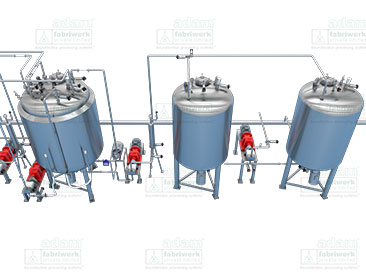

We provide customized, end to end solutions for liquid oral plants that are fully automated with SCADA controls or semi-automated as required. Our plants are designed with the highest quality of fabrication standards using the best components and instruments. They are also fully optimized for delivering the best performance with reduced life-cycle cost.

Our systems are designed for optimization of key resources and designed with features that include;

We provide customized, end to end solutions for liquid oral plants that are fully / Semi automated design

Sugar and raw material suction by vacuum into the processing vessel

Fully controllable and precisely adjustable vacuum system ensures efficient product transfers

Tanks fabricated with superior SS316L, all components and instruments sourced from reputed international vendors