Having worked with many top pharmaceutical companies, we understand the need for not only creating modular and scalable production lines but also systems that are highly efficient and with lower operational costs. Our systems deliver just that.

Achieving operational efficiency also demands high end automation with highly reliable control and monitoring systems that are easy to operate and validate. Our expert process engineers understand your process and engineer a fully customized solutions to suit your exacting needs.

We enable processes that deliver consistency, is efficient and easy to validate

While our customers demand highest yield and quality, we enable this in the most efficient manner ensuring greater system control, easy operation, easy cleaning and easier validation.

Our manufacturing process has been time tested while dynamically evolving to be in sync with the needs of our customers and the industry as a whole. While the macro-steps have largely remained the same the micro-steps have undergone multiple refinement cycles.

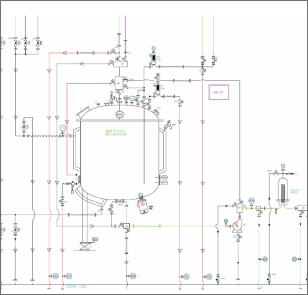

The system manufacturing process is initiated with the preparation and approval of P&ID drawings. The P&ID accurately captures the arrangement of all instruments, equipments and component like the Vessels, Pumps, Valves and instruments. Once the P&ID is approved, the process of creation of General Assembly (GA) drawings is initiated

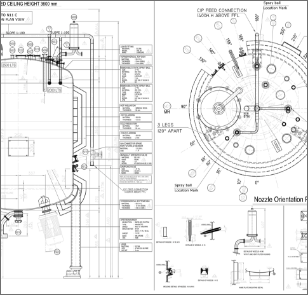

The General Assembly drawings deliver information like the dimensional details, design parameters, quality of surface finish (Ra values), BO specs etc. On approval of this, we proceed to the next stage i.e. 3D design of the system.

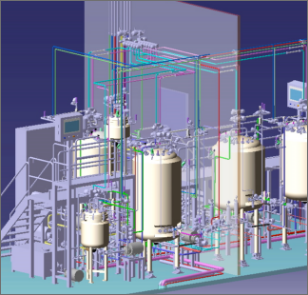

We use the latest state of art 3D visualization and simulation software like CATIA & SIEMENS NX. These are great tools for engineering, visualization and simulation. They are also of great help in understanding the integration, size, scale and issues that might arise at the site during the installation and integration with other systems.

On the basis of the 3D model, the systems are manufactured, assembled and tested. The use of 3D softwares ensures that minimal time is taken to assemble and integrate the system without any delays. The system is then checked for compliance and deviations with the P&ID, GA and the 3D models.