At Adam Fabriwerk, we understand the importance of validation. Our Quality Assurance team provides close assistance to our customers, throughout their validation cycle.

We have a dedicated, in-house Factory Acceptance Test (FAT) facility that is fully equipped with all the required utilities to ensure the systems that are ready are thoroughly tested and documented. Our QA team works closely with our clients to understand the validation and documentation needs and ensures the requisite support. Deviations are documented, attended to and cleared for inspection and shipment on approval.

Our Quality Assurance team ensures delivery of all the required documents like test certificates, MOC, Drawings, P & ID, Weld certificates, Mill certificates, Calibration certificates etc., are compiled organized in an easy to retrieve format.

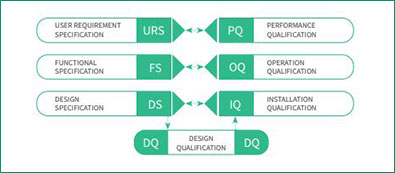

The QA team ensures full support for validation at the site and assists to qualify the system during installation as well as during the operation of the system.

We at Adam Fabriwerk fully understand the need for a thorough evaluation to check if it is in accordance with the Design Qualification. That is why we have built a fully equipped world class facility to conduct the FAT.

High quality testing instruments ensure the systems work fine under the designed conditions. Our QA team ensures complete documentation that are required before and during the FAT while these tests are carried out.