Left drag with your mouse. Click on hotspots to see additional information as video, image or explaination

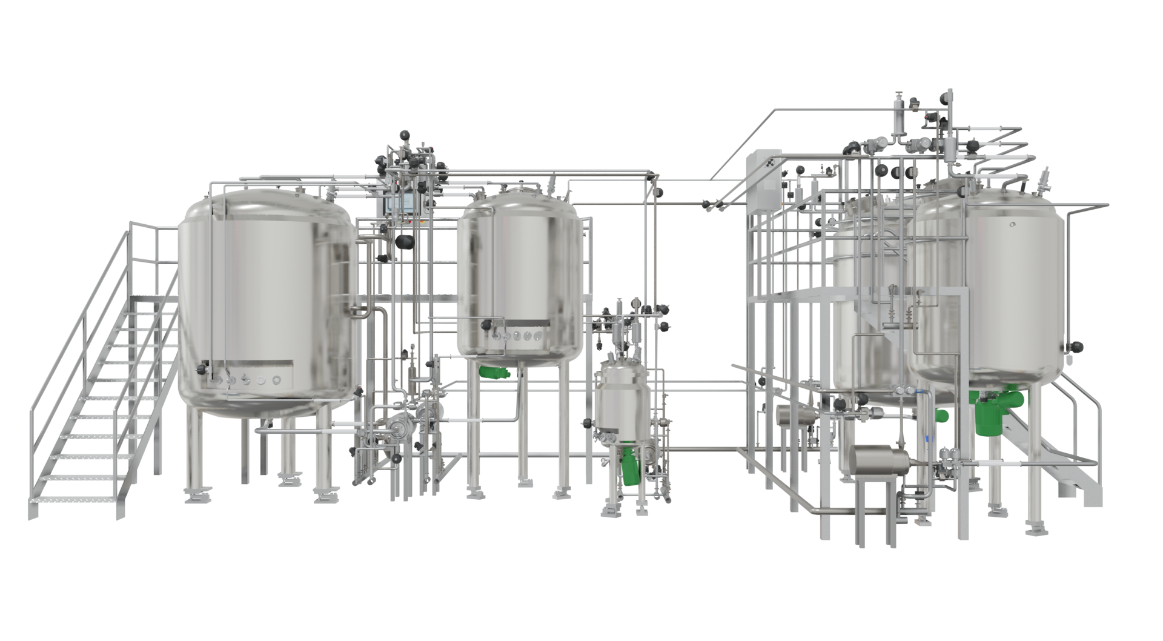

Super skids are fully integrated plant assembled and tested at our facility and shipped in assembled condition to your facility.

Superskids drastically reduces your project ' Turn Around Time', including the time for system validation. Our spacious manufacturing facility allows us to build fully integrated very large sized systems, the 'Super skids' are shipped directly to the project site and installed as fully integrated plant.

When the plant is shipped in assembled condition to your facility, a lot of site activity and time is reduced.

Modular construction enables you to scale your production easily without breaking the integrity of the existing plant.

Convert the FAT easily to SAT and reduce the installation, commissioning and qualification time drastically.

Eliminate installation and Commissioning time and effort at the site. Factory integrated means better workmanship and quality

This means ease of scaling. You can start with lower capacity and scale up easily when your product demand goes up

Bottom mounted magnetic mixers with options for low / medium / high shear applications

The system is engineered with world class instruments to monitor and control critical parameters like volume, Temperature, Pressure, DO, Conductivity, pH etc.